Common FAQ’s – Golf Course Robotics

Introduction

For the past 15 years, Range King Ireland and its dealer network have specialised in supplying, installing, and maintaining robotic machinery for sports fields. The early models of these robotic mowers operated on wired systems, as GPS technology was not yet available. Fourteen years ago, Naas RFC became the first commercial user of these first-generation robots in Ireland and has since upgraded to a GPS-RTK system working off a 4G RTK mast. The Meath & District League (FAI) followed as the second adopters, investing in two classic line robots to mow three soccer pitches that remain in use to this day.

Fast forward to 2022, and with advancements in technology, autonomous straight-line robotic mowing has become commercially available. Boyle GAA in Roscommon was the first sports club in Ireland to adopt a GPS-RTK straight-line robot, proudly supplied and expertly installed by Range King Ireland. Today, with over 120 commercial GPS robots installed, Range King has established itself as the leading provider and installer of robotic machinery for sports fields across the island of Ireland, including Northern Ireland.

Fast forward to 2024: the year of the fairways. With significant advancements in GPS-RTK technology for robotic mowers and major strides in refining both software and hardware, the BigMow GPS-RTK for fairways is born. Features like upgraded slope gearboxes, height adjustment body spacers, robotic fleet management at your fingertips, sequential scheduling, clean-up laps, and low-height cutting heads represent just some of the innovations.

Roganstown Golf Club and Swords Golf Club in County Dublin has successfully installed, 7 BigMow 4G RTK robots, with Range King Ireland utilizing 15 years of expertise in robotics to bring the McGuinness brothers’ vision to life. Their goal was to deploy a complete fleet of robotic fairway mowers to revolutionize golf course maintenance with an eco-friendly approach. This initiative not only enhances surface playing quality for members and visitors but also reduces staff workload and ensures greater surface consistency all year round. The Driving Range has also been fully automated with automatic ball collection and washing.

Two other golf courses are currently installing Bigmows and will be completed by December 2024 (for further details contact info@rangeking.ie)

Below is a Q&A-style questionnaire addressing the most common questions we receive from golf courses. The questions are categorised under five key headings: operations, maintenance, installations, costs, and golfer-player considerations.

Operations

1) What size/width do the Belrobotics robot mowers come in?

The largest of the fleet, the Big Mow 2050, has a cutting width of 103.5cm. Down from that is the Parcmow 1050 which has a cutting width of 64cm. And finally the BM850 Sport which has a cutting width of 35cm.

2) How much does the robot cut in 24 hours, which includes charging time?

The real capacity test of a robot’s cutting capacity is how much grass can the robot cut in a 24-hour period. A BigMow RTK can cut 30,000m2 in a 24-hour period depending on the complexity of the installation.

3) How long does it take to charge each time?

It takes about 1 hour for the robot to charge fully.

4) How long does it take to cut fairways on an average 18-hole golf course?

Depending on the number of robots working on the course and the complexity of the installation, 3 robots would cover an 18-hole course working full time in approx. 35 hours, including charging time.

5) How many robot mowers are recommended to cut fairways on a standard 18-hole golf course?

Depending on certain requirements and the complexity of the course, a typical 18-hole golf course would need between 3 to 5 robots to cut fairways and semi rough (step-cut) only.

6) How many robots would a typical Par 3 course need?

Depending on certain requirements, a typical par 3 course would need between 1 to 2 robots to cut fairways and semi rough.

<PHOTO HERE>

7) How many cutting blades are there on each robot?

On the BigMow, there are 5 cutting heads with 3 double-sided blades on each.

8) Can they be left to operate/cut without supervision?

Yes. These robots are fully autonomous, day and night. It is legal to have them operate without supervision.

9) How well can they contour on undulating ground?

Thanks to the patented floating head design, the BigMow can manage gradual undulating ground very well down to about 12mm. Each head moves independently as it glides over undulating ground.

10) What is the highest and lowest height the robot can cut at?

The highest the BigMow can cut at is 100mm, and the lowest HOC is 12mm using the special fairway cutting disks.

11) How is the height of the blades set?

The height can be set remotely using your phone. The height of the blades can be set per unique working area and will be adjusted automatically depending on what has been inputted in the parameters for that area. When leaving the charging station to go to a working area and returning home, the blade heads will rise automatically while in transport mode.

12) What gradient are they capable of climbing?

The BigMow is capable of climbing slopes of up to 45% with the specialised upgraded slope gearboxes.

13) Does weather affect the operation of the mowers?

The robots function normally in rainy weather, although slight slippage may occur in very wet conditions. To mitigate this, we offer upgraded wheel spike attachments that secure to the outside of the drive wheels for improved traction. Additionally, the robots are equipped with built-in thermometers, allowing users to set a custom minimum operating temperature. For instance, if the temperature drops to 2°C overnight and the minimum threshold is set to 3°C, the robot will automatically return to its charging station and remain there until the temperature rises above 3°C. This convenient automatic feature ensures optimal performance and protection for the grass.

14) In Wintertime, lakes can rise to a different level than they do in the summertime. How do you manage this?

Easy. Increase the size of the GPS no-go zone via the online portal whenever the end-user deems necessary.

15) What are the GPS costs per year?

For a 4G RTK set-up, a typical yearly subscription for the App, Portal and 4G cellular RTK transfer between robot and mast (15km radius reach) works out about €445 on the first robot, and €250 on each robot after. You also have the option to purchase a GPS Lifetime package, a once off payment which will set you up for life and never receive a GPS bill. Ever.

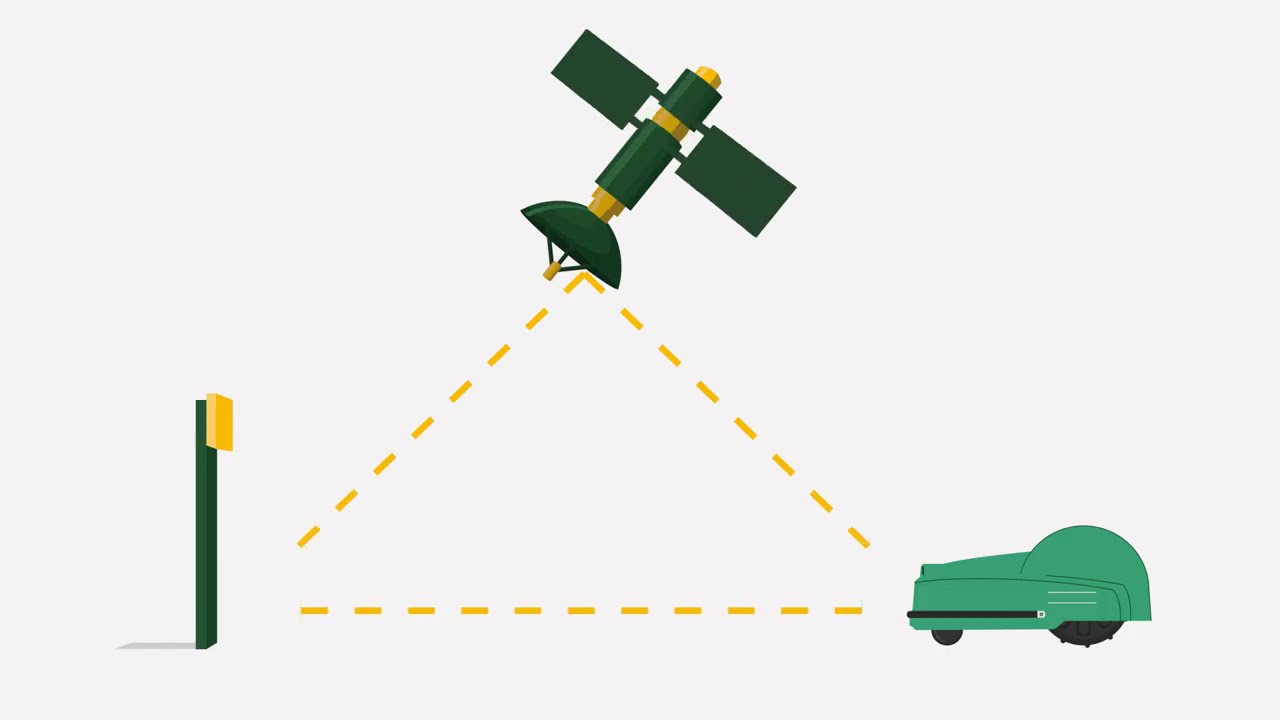

16) How does the GPS system on the mowers work.

The successful operation of the BigMow’s GPS-RTK system relies on three key components: an RTK mast, a GNSS antenna within the robot, and the satellites. GPS-RTK (Real-Time Kinematic) provides robotic mowers with centimetre-level positioning accuracy. It uses a fixed base station (RTK mast) to calculate GPS signal errors and send real-time corrections to the robot mower, which applies them instantly for precise navigation. The technician maps the fairways using GPS points and in turn the robot navigates pre-defined/calculated paths and avoids obstacles using sensors. The robot communicates with the RTK base via 4G cellular signal.

Maintenance

17) What’s the maintenance costs per year?

Each year, the robots undergo an annual winter service to ensure optimal performance and longevity. During this service, the gearboxes are overhauled with fresh grease, motor bearings are inspected and replaced if needed, and calibrations are performed. Any additional maintenance required is also carried out. A comprehensive service test is conducted, with the results recorded on the portal and a printed copy provided for the end-user’s review. The cost for a full service on a BigMow is €600 plus 13.5% VAT per robot.

18) How often is it recommended to change the cutting blades.

The timing for blade replacement depends on a few factors, but it’s typically needed when the blades start to form a “V” shape or when a white tip appears on the grass blades, indicating shredding instead of a clean cut. On average, blades should be replaced every 6to 8 weeks. For fairway mowing, we recommend our specially designed tungsten-tipped blades, which offer exceptional durability.

19) Is it simple to change the blades on the mowers?

It’s very straightforward—the blades on a BigMow can be completely replaced across all five cutting heads in just 15 minutes.

20)How much are the blades for the robot mower?

Each tungsten-tipped blade costs €2.80, so replacing the full set of blades on a BigMow comes to a total of €42.

21) What is the body of the machine made of?

The body of the robot is made from injection moulded plastic which has a double shell for ultimate durability and protection, unlike other robots on the market.

22) What is the average life expectancy for the mower?

The robot is built with a stainless-steel chassis, offering resistance to rot and deterioration. Its body is crafted from double-shell injection-moulded plastic, ensuring exceptional durability. Over time, the only mechanical components that may need replacement are motor bearings, occasional control cards, and sensors. Designed for longevity, the robot’s body and chassis have an estimated lifespan of around 25 years.

23) If a robot mower breaks down what back up service is available?

At the time of installation, we provide all clubs with the option of a maintenance contract that includes remote technical support for diagnosing and resolving issues, often eliminating the need for an on-site technician. As the primary distributor and installer of these robots in Ireland, we maintain a comprehensive parts warehouse, enabling us to ship replacement parts directly to users within 1-3 working days. If an on-site visit is necessary, it can typically be arranged as soon as the next day. Additionally, our nationwide dealer network is fully trained in the installation, servicing, and maintenance of these robots, ensuring reliable backup support whenever needed.

24) How many moving parts are on the machine and how are they maintained?

During operation, there are a total of 8 moving parts. 2 drive motors, 5 cutting motors and 1 automatic height adjusting motor.

25) How much time is spent on average checking the mowers each day?

It is recommended to inspect the robots each morning as part of good maintenance practice. Use a battery-powered blower to remove any excess grass once per week. On average, users should allocate approximately 10 minutes per robot each day for this routine.

<PHOTO HERE>

Installation

26) Is it required to have different charging points around the course?

Each robot requires its own dedicated charging station. So if you have 5 robots then you need 5 charging points. For more complex installations, robots can navigate multiple GPS-guided paths between the charging station and their designated working areas.

27) What is required to set up the charging points for each mower?

The first step is to develop a clear plan for the course layout and determine the precise locations for the charging points. Once this is established, a 220V power outlet with a blue socket must be installed within 5 meters of the designated charging station location.

Costs

28) What is the Battery life span, and do they come with warranty, if yes what is it?

With proper care and maintenance during the winter, the battery has an average lifespan of approximately 8 years. We have robots still out working with the original battery, which are over 8 years old. The robot comes with a 2-year manufacturer’s warranty that covers most components, with the option to purchase an additional 3-year extended warranty for added coverage.

29? What is the average overall cost of charging per year per mower.

The annual electricity cost for a BigMow is approximately €280, as verified by the manufacturer.

What is the cost of a BigMow RTK, and what would be the overall expense for a golf course to implement a fleet of these robots?

this depends on the course configuration etc. For any pricing queries, please email info@rangeking.ie and following a free survey we can determine the total cost.

<PHOTO HERE> Roganstown

Golfer-Play Considerations

30) What happens if a player or a golf ball are in proximity to the mower?

When the robot encounters an obstacle, such as a player, its sonar sensors detect the object and slow the robot to a crawling speed as long as the obstacle remains in its path. At this speed, the robot gently makes contact with the obstacle, which triggers its bumper sensor. The robot then adjusts its course to manoeuvre around the object. The operator also has the option to make the robot “wait” for a bespoke time period once the robot sonar sensor picks up something in front of it.

In early 2027, an AI camera retrofit will be available to purchase for all Belrobotics robots. This will allow much more control over what happens when the robot detects a golfer or a golf ball in front of it.

31) What safety features are built into the robot to help detect golfers?

Equipped with onboard safety sensors such as obstacle detection, bump detection, lift detection, and collision detection, the robot mower is entirely safe for use around golf club members. All safety and manufacturing certifications are readily available for review, either before or after the purchase.

If you require more information or have any questions please contact info@rangeking.ie